Hello all.

First of all thanks for everyone's contributions here! You posts have given me endless hours of research and pondering in preparation for my first CNC plasma table build with water table (Occasionally for a home project I would like the option of using a router on it as well).

The time has come to take the plunge so I though I would get a thread started to document/get advise/brainstorm ideas. I plan an building a table that is able to cut/scribe minimum edge to edge of a 4'X4" sheet. I would have liked to build a larger table but I have to fit this into a 20' long shipping container that I purchased for my shop. Still in the planing stages for the details of the design but I have been inspired by dnelso's builds so I'm hoping to build roughly the same design. Although I do not think the budget is going to allow for all the fine details like dnelso has.

I was planning on using a Hypertherm Powermax 45 but last weekend I scored a Hypertherm Powermax 1000 G3 that is in excellent shape for $1200. It has a hand torch that I think I will just convert to a machine torch for now.

I started ordering of parts:

From Automation overstock I ordered:

Ordered 6 AGW25SAZ1C 25mm Bearing Block, 2 Bolt Flanges (they were sold out of 4 bolt) and AG 25 R Rail Sections 2 x 1700mm 1X 1550mm

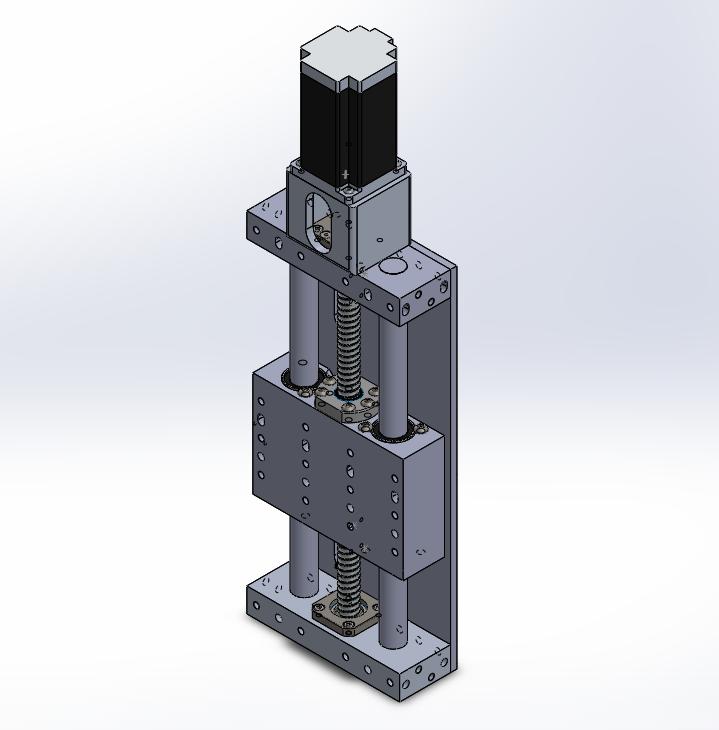

Z axis I will make myself (Hoping for aprox 6" travel)I have 20mm rods and bearings ordered and a Ballscrew1605-365mm (Φ:16mm Pitch:5mm L:365mm) end machined+ballnut+FK/FF12 end supports

Haven't Nailed down the rack on pinion choice or supplier yet. X+Y axis will have belt driven gear reduction. I keep flip flopping on having it spring loaded to automatically take up backlash or not.

For motors/control I plan on using CandCNC ETHER-CUT MARK IV 620-4...although not sure if I should just get the Dragon cut system?

Guess that's about it for now, just waiting on the postman so I can start on something!

Results 1 to 20 of 58

-

11-27-2014, 01:45 AM #1

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Eric's 4'x4' CNC Plasma table build

-

11-30-2014, 02:45 AM #2

Registered

Registered

- Join Date

- Nov 2014

- Posts

- 5

Re: Eric's 4'x4' CNC Plasma table build

good luck on the build

-

12-02-2014, 07:31 AM #3

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

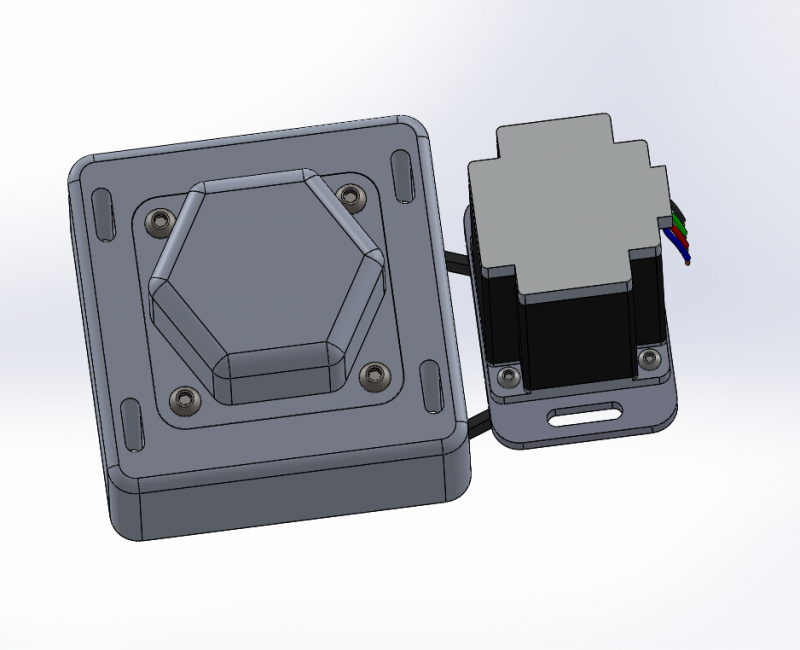

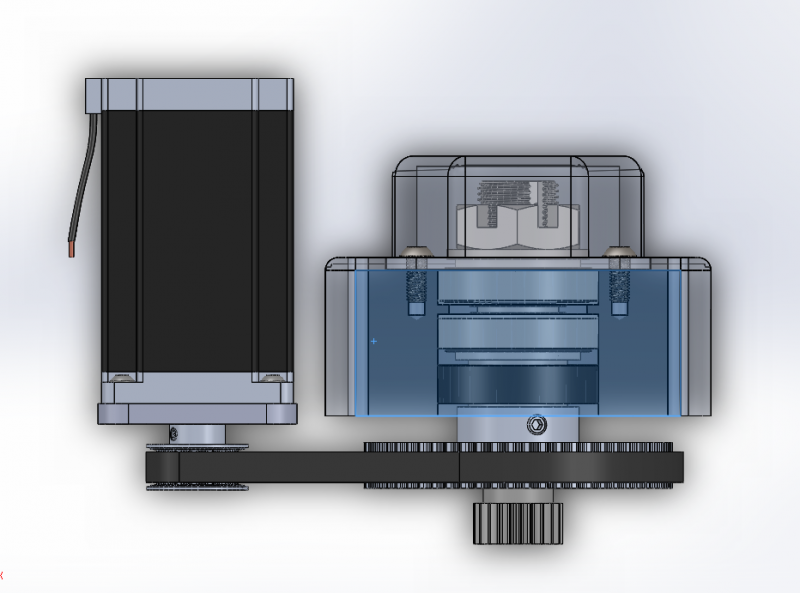

I'm think of trying to inboard the gantry motors to save a bit of space. Have them mounted inside the gantry cross bar like in these photos. Except on mine the center distance between pulleys would be approximately 12"

Couple things that worry me about going this route would be the longer timing belt causing more backlash and I am not sure if the motors would over heat located inside the square tubing.

What are your thoughts?

-

12-22-2014, 09:03 PM #4

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Decided against installing the motors inside the gantry like above.

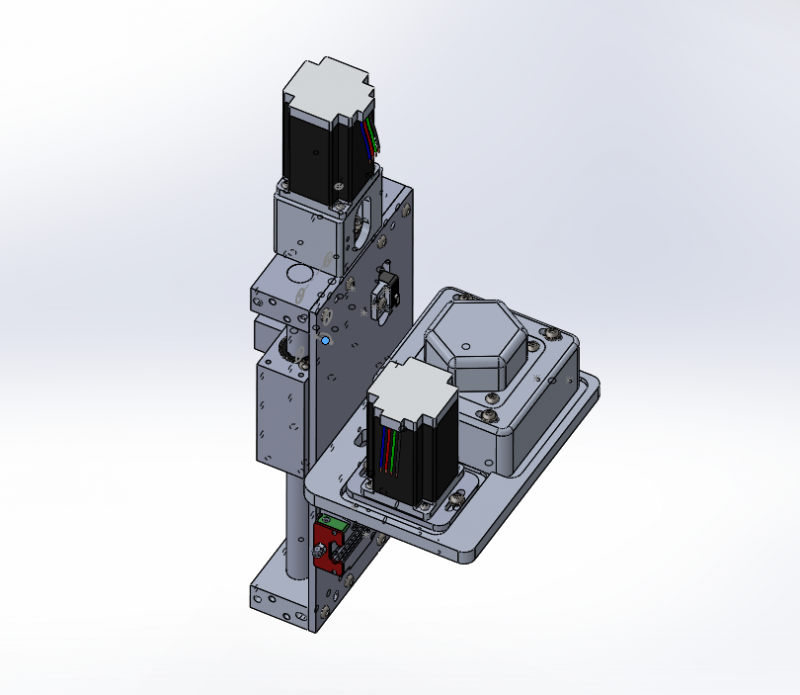

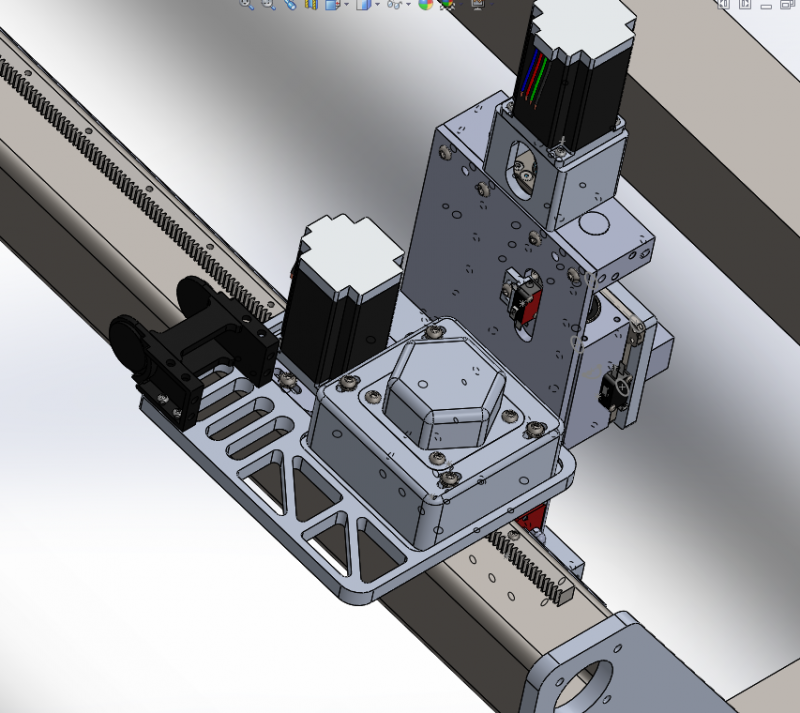

Been working on designing the table in CAD.

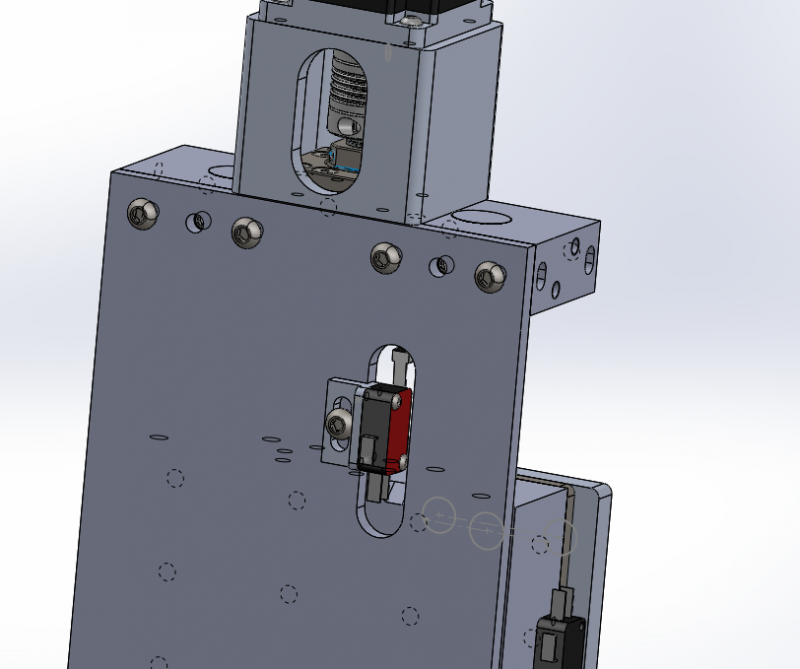

Z axis is pretty much finalize. Not reinventing the wheel here. It was though to package everything the home and over travel limit switches were moved to the backside so I could easily adjust their positions or replace them. Total travel at the moment is 6.75".

I received all the parts need to build the Z axis so construction should start after the holidays.

Just a not DO NOT take the nut off of the ball screw I should have known better but I though there was a cage or something to hole the ball bearings in place....it's going to take a while to put it back together.

I should have known better but I though there was a cage or something to hole the ball bearings in place....it's going to take a while to put it back together.

-

12-23-2014, 07:56 AM #5

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Thanks to this video my ball nut is repacked. Mine didn't go as smoothly as the video for the first circuit but it works again!...I was worried for a minute. lol

Well, at least I know how it goes together now and I will make sure I can build the Z axis WITHOUT removed the nut.

-

01-08-2015, 07:58 PM #6

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

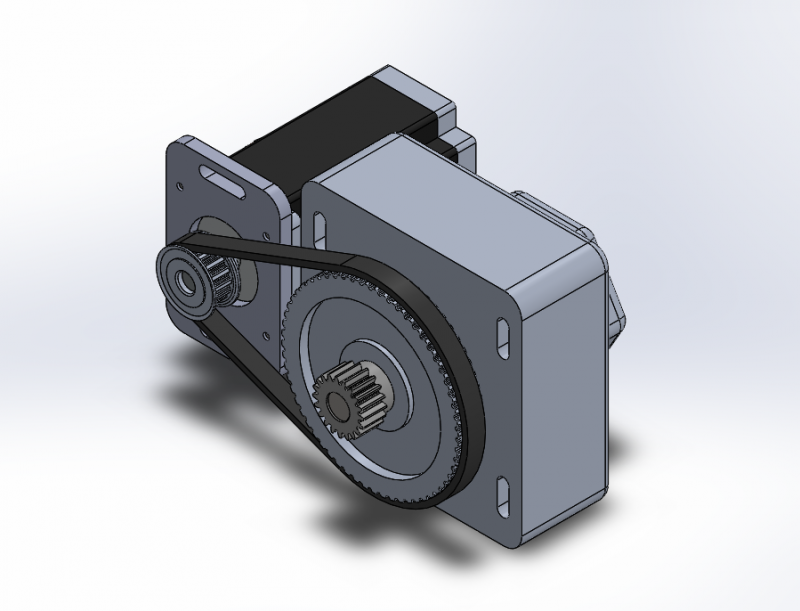

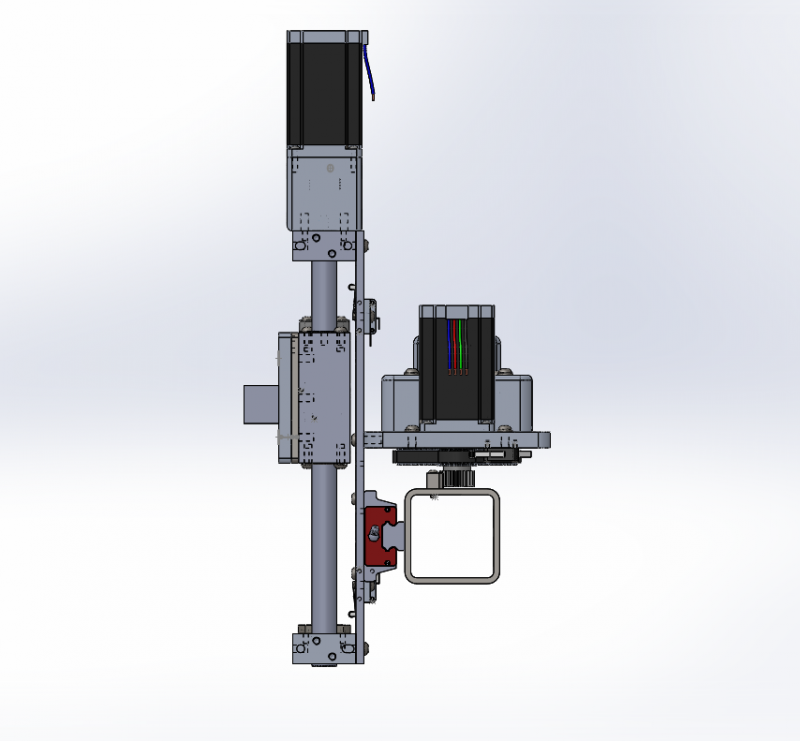

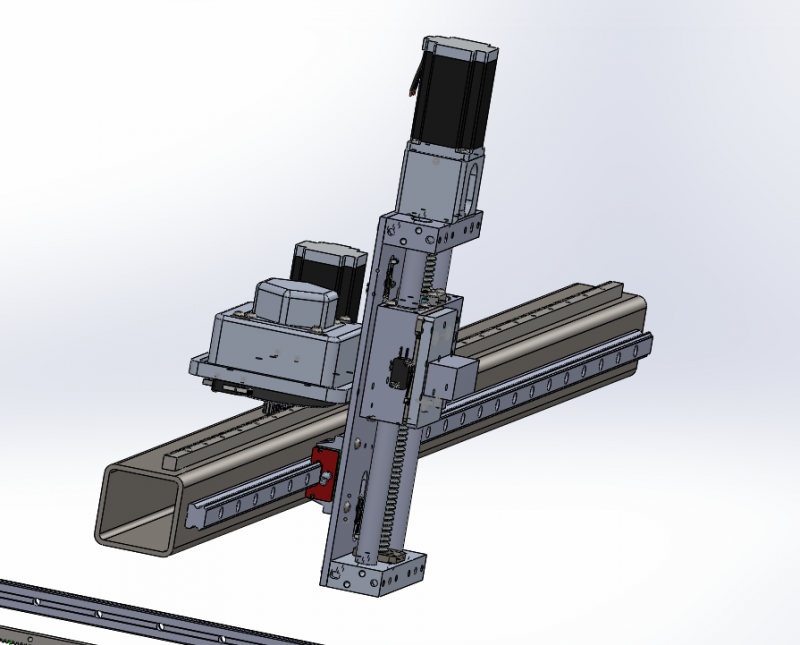

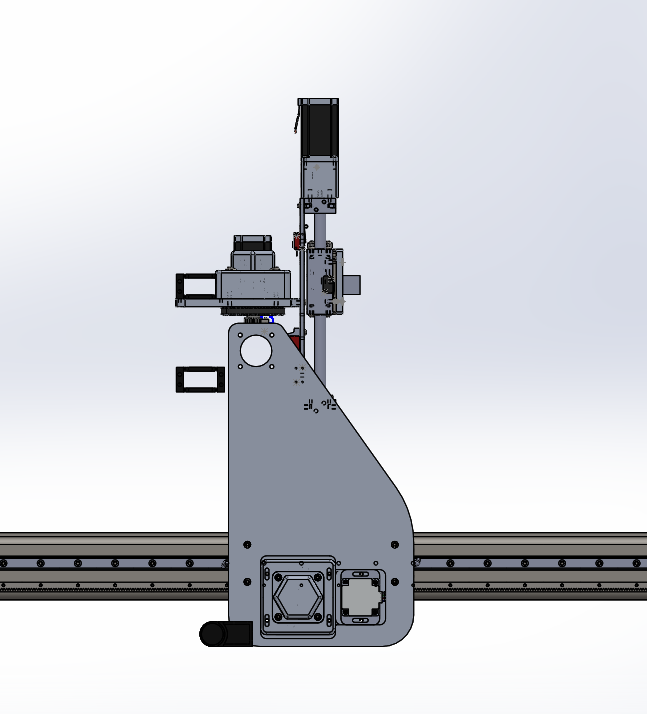

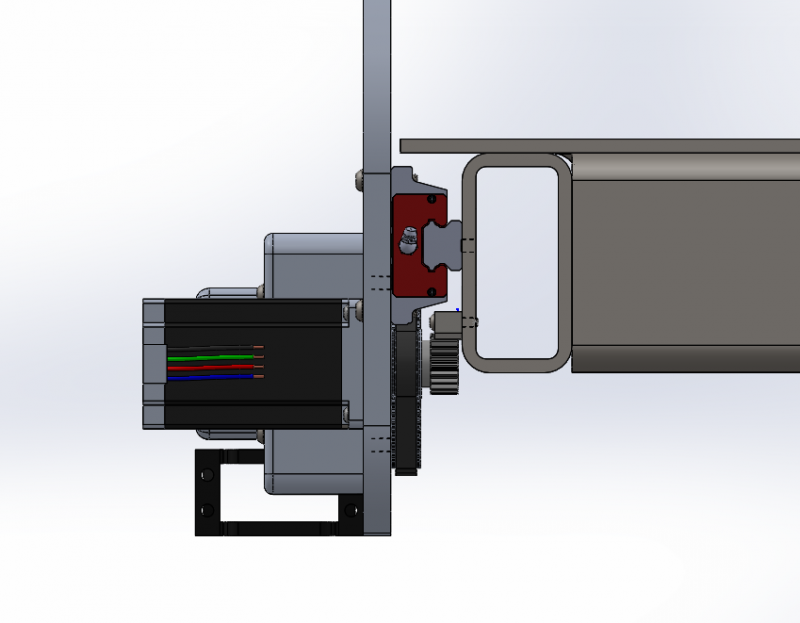

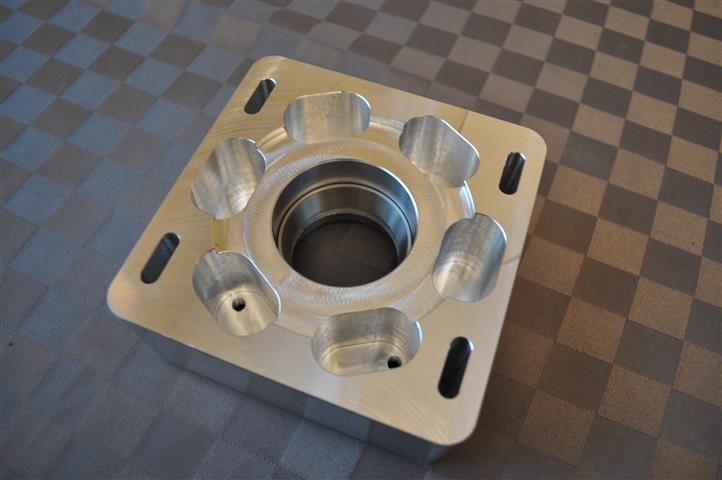

X+Y axis will be driven by rack and pinion. Will need a reduction drive for the stepper motors. It will be a 3.75:1 reduction but it can be changed if I want something different in the future.

Using a 1" trailer spindle bearing kit since they are handy and come with a grease seal as well.

Y Axis Drive mounted on backside of the Z axis.

-

01-09-2015, 08:12 PM #7

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

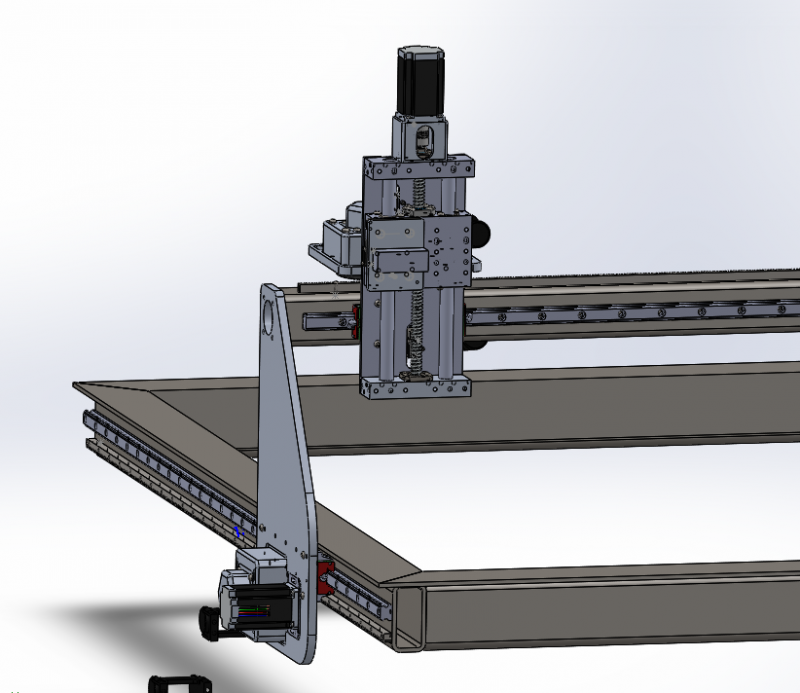

Re: Eric's 4'x4' CNC Plasma table build

A axis, rails and rack mounted on gantry cross beam. Haven't decided on the material for the beam yet. Initially was thinking 3'X3" 3/16" steel but I'm getting worried about the 100lb max my gantry can wait so I might give 3'X3" 1/8" aluminum a try and see how it goes. With the 1/8" thick aluminum I would have to ditch just threading the beam and use nuts and washers. I'm not sure if M6 threads in 1/8" thick aluminum would hold up?

-

01-09-2015, 11:33 PM #8

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Figured I was okay keeping the reduction drive the way it is and am getting excited to start building something. So the machining begins!

1st side of the bearing block

2nd side. Sorry only photo I took.

3 complete. I should be able to heat them up and slide in the races tonight.

I also started the 1st side of the drive shafts. I'm waiting to commit on the end that the pulley mounts on since It's still in the mail. Also the final length may change yet.

Bearing and seal diameters turned manually

I've been spoiled by working with a CNC so I machined the threads and slot on the mill.

Drive shafts complete 1st side.

Bearing block covers. Done.

The cable drag chains showed up yesterday so at least now I can finalize the Z axis and gantry positions. I tried to find something with a large bend radius and within budget. These are 75mm rad and 25mm X 57mm internal.

Back to the CAD.

-

01-12-2015, 01:54 AM #9

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Extended the Y axle motor plate to make room for the drag chain. A little worried about the overhang. Thinking about adding a support bracket to keep the plate from wobbling.

1/2" thick Aluminum gantry uprights. Still a work in progress. At the moment there will be 7.5" clearance to bottom of Z axis to top of slats. Once I finalize positions of everything all cut some pockets in to remove some weight.

Going to use 3.5"X3.5"X.25" Angle for the water table perimeter. It will allow for a nice overhang to protect the ways and gear rack.

-

01-12-2015, 04:35 PM #10

Registered

Registered

- Join Date

- May 2006

- Posts

- 238

Re: Eric's 4'x4' CNC Plasma table build

Looks Good. Keep posting pics.

Dave

-

01-12-2015, 07:19 PM #11

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Thanks Dave. Could I ask if you used 1/2" thick plate on the gantry uprights for your builds? Is there any wiggling?

-

01-12-2015, 09:46 PM #12

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Why not use some 4x3 or even 2x3 8020 extrusion? That stuff is way more rigid than a normal tubing and wont weight as much as steel either. My cnc waterjet uses extrusion for all 3 rails on the gantry assembly in x and y and the gantry probably weighs close to 300lbs

-

01-13-2015, 01:08 AM #13

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Cost would be the main reason. Second would be I'm not a fan of all the nooks and carnies to collect dirt in. I would have to make covers for it.

I'm leaning toward using 3"X3"X1/8" aluminum. The stuff we have at works seem much more square than the larger stuff. The linear rail and gear rack should help stiffen it up.

Also I was thinking about running the angle that will support the drag chain across the entire length to help re-enforce it.

-

01-13-2015, 01:12 AM #14

Registered

Registered

- Join Date

- Aug 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

They make a "smooth" version, and they sell "covers" for the tslots. 3x3x.125 will hardly be as rigid as you think. maybe ok for a 4x4? but still..a cost of the extrusion would only be around $200-300 shipped maximum and it will be perfectly square and you wont have to drill/tap any holes.

-

01-13-2015, 01:25 AM #15

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

I'll look into them. Thanks.

-

01-13-2015, 04:14 PM #16

Registered

Registered

- Join Date

- May 2006

- Posts

- 238

Re: Eric's 4'x4' CNC Plasma table build

My plates are 1/2 and work fine.

-

01-13-2015, 06:00 PM #17

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Thank you.

-

01-17-2015, 08:44 PM #18

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Parts for Z axis are in so I can start machining.

20mm Linear Slide Bearings and rod.

5mm pitch ball screw and mounts (may have to make a cover for it in the future).

Found a slightly used bellows type motor coupler on ebay. Over kill for a plasma but if I ever use the table with a router it will help improve things.

Picked up some material for the Z axis.

Z axis slide

Raw block

1st operation. I have added .25" bores and slots to help to line up anything that I mount to it.

2nd operation. Just for fun cut some weight off it. 2 whole ounces BUT it's off every axis lol

Lost two operations were the bearing bores and ball nut mount. Sorry I didn't take photo's on that machining.

Done

-

01-17-2015, 08:53 PM #19

Registered

Registered

- Join Date

- May 2013

- Posts

- 53

Re: Eric's 4'x4' CNC Plasma table build

Also cut some speed holes in the underside of the three reduction drive bearing blocks. I'm sure I could take more off but I'm okay with the 2.25lb total weight savings at the moment.

-

01-18-2015, 01:59 AM #20

Registered

Registered

- Join Date

- Sep 2011

- Posts

- 54

Re: Eric's 4'x4' CNC Plasma table build

Eric, your machine work looks awesome.

Similar Threads

-

Plasma Table Build

By knowlzy1824 in forum Plasma, EDM / Other similar machine Project LogReplies: 5Last Post: 10-22-2014, 01:12 PM -

Newbie - To build or not to build Router/Plasma Table

By dfranks in forum Waterjet General TopicsReplies: 10Last Post: 04-08-2011, 05:16 AM -

My 4x4 Plasma Table Build

By unixadm in forum Plasma, EDM / Other similar machine Project LogReplies: 8Last Post: 06-20-2010, 05:51 AM -

5 x 10 plasma table build

By DSL PWR in forum Plasma, EDM / Other similar machine Project LogReplies: 23Last Post: 10-14-2007, 10:09 PM

Reply With Quote

Reply With Quote