I have a denford triac and the sem motor inside has seen better days.

I note a lot of people are changing their motors for these Chinese ones with high rpm rates.

but im finding it impossible to get hold of a full spec for them, like a torque curve? can anyone help?

Results 1 to 16 of 16

-

09-19-2014, 09:09 AM #1

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Chinese 2.2kw Spindle - wanting full spec

-

09-19-2014, 11:12 PM #2

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

im guessing the lack of responses means people are buying them without checking the full spec?

-

09-20-2014, 02:19 AM #3

Registered

Registered

- Join Date

- May 2010

- Posts

- 120

Re: Chinese 2.2kw Spindle - wanting full spec

Hi,

I've never seen motor specifications for the chinese spindles except the most basic stuff like base frequency, voltage and power rating.

The best approach would be to ask one of the sellers directly - maybe they have additional information (but most likely not).

The torque curve depends on the VFD you use. Don't expect much torque at low rpm with the usual chinese VFDs - at 4000rpm you can easily stop the spindle by touching it with a finger.

A VFD with vector control will work much better - especially as the water cooled spindles do not require a minimum rpm for cooling purposes. But don't expect too much - they are designed for high rpm and small diameter tools.

ChristianMy CAM Software and CNC Controller: www.estlcam.com

-

09-20-2014, 09:02 AM #4

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

Thanks for your reply, I did ask an eBay seller and they didn't know what I was talking about.

my machine has an atc so the curent sem motor is connected via a cog and belt. the plan would be to use a 2:1 reduction as i dont need 18000rpm, 9000rpm would be perect.

i machine aluminium and sometimes steel, i use like a 20mm cutter daily

i see someone has already done it on a denfor triac

-

09-20-2014, 09:20 AM #5

Registered

Registered

- Join Date

- May 2010

- Posts

- 120

Re: Chinese 2.2kw Spindle - wanting full spec

Hi,

I'm a bit confused now - I thought it was about the complete chinese spindles with collet chuck - but it seems like you just need a new AC motor?

ChristianMy CAM Software and CNC Controller: www.estlcam.com

-

09-20-2014, 09:28 AM #6

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

No, not an atc motor. I'm after a new spindle motor, but like I say the motor connects to the spindle via a cog and belt

-

09-20-2014, 05:28 PM #7

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

Also can you use m3 and m4 commands with these motors so it goes clockwise and anticlockwise?

-

09-20-2014, 11:56 PM #8

Member

Member

- Join Date

- Jan 2005

- Posts

- 15362

Re: Chinese 2.2kw Spindle - wanting full spec

andy_con

Yes you can, but this is controlled by the VFD & your control, they are a 3 phase 2 pole AC motorMactec54

-

09-21-2014, 07:46 AM #9

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

-

09-21-2014, 12:36 PM #10

Registered

Registered

- Join Date

- May 2010

- Posts

- 120

Re: Chinese 2.2kw Spindle - wanting full spec

Hi,

I think there are some things mixed up:

- The "chinese spindles" are complete units with manual collet chuck - no ATC.

- Yes - you may be able to use them with cog and belt in theory - but it is no good solution due to the collet chuck and missing mounts.

- What you need is most likely just any generic 3-phase AC motor with the desired rpm range and a mount similar to the one just used in your machine.

They are mostly standardized and rather cheap even if manufactured in Europe or the US. - Except: if your machine uses a servo motor (has a very large rpm range without gearbox / is able to cut threads) you'll need a new servo motor.

In this case you should stick to the original manufacturer or a replacement with exactly the same specifications and be prepared to spend serious money. The chinese spindles are no match for something like this.

This is - like the torque curve - not just a motor property. It depends also on the VFD (driver) capabilities but should be standard nowadays.

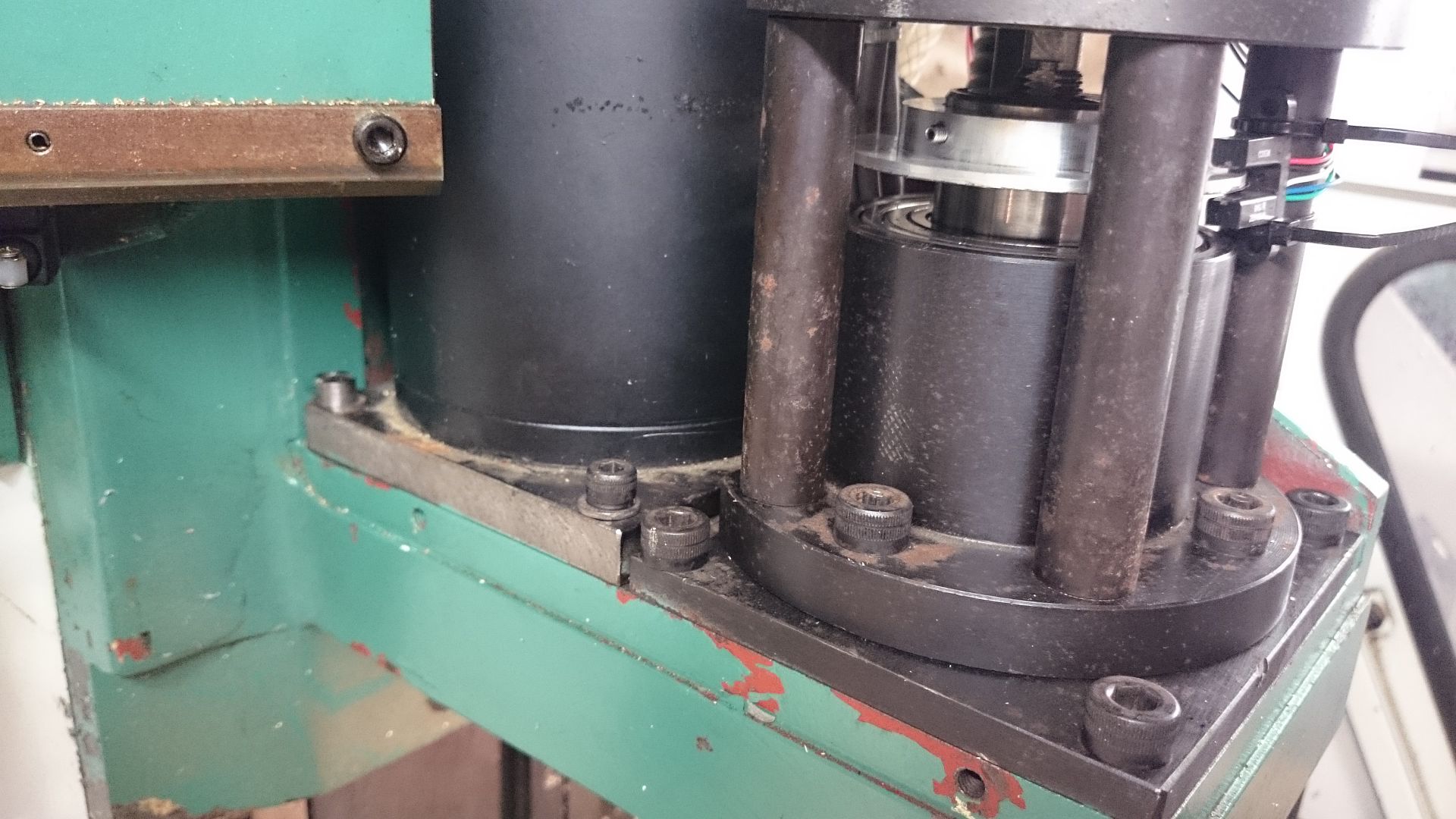

Can you post a picture of the current motor? This will make things more clear.

ChristianMy CAM Software and CNC Controller: www.estlcam.com

-

09-21-2014, 03:23 PM #11

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

ok lets clear this up then

machine head

sem servo motor at the back, with air feed power draw bar at front

and again motor at the back and power draw bar at the front.

on the end of the sem servo motor is a pulley which connects to a the spindle via a belt

so as ive said the plan would be to remove the sem motor and replace with a Chinese 2.2kw or 3kw motor

I would make a custom pulley to go on the end of the new Chinese motor so that it can be connected to the belt and drive the spindle and keep the atc

does that make sense now?

-

09-21-2014, 03:51 PM #12

Registered

Registered

- Join Date

- May 2010

- Posts

- 120

Re: Chinese 2.2kw Spindle - wanting full spec

Hi,

I would not do this. At the moment you have a quite solid machine with a decent servo motor.

It may be old and a bit outdated (seems to be a DC type motor - I can see a brush holder) but as long as it works I wouldn't change anything.

The chinese spindle will be no match - and a replacement motor will cost a fortune.

But most important: it is totally different technology regarding the electronics. You'll need to change anything related to motor control - and maybe even the whole cnc controller.

ChristianMy CAM Software and CNC Controller: www.estlcam.com

-

09-21-2014, 04:46 PM #13

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

Although generally its a great motor (£1500 new just for the motor), its got a problem. Something is up with the speed control part. It keeps revving up and down it won't stay constant

So its either £500 for a repair or £600 for a new Chinese.

I've got a pmdx breakout board so shouldnt need a new one

Currently motor is 4000rpm at 1.5hp

So at 4000rpm I can run a 6mm cutter at about 250mm per min

I'm thinking 10000rpm means around 500mm per min

This is my wild dream

Like a hot knife through buttet

-

09-21-2014, 05:26 PM #14

Registered

Registered

- Join Date

- May 2010

- Posts

- 120

Re: Chinese 2.2kw Spindle - wanting full spec

Hi,

Check and clean the encoder. If the encoder is OK its most likely the control circuit but not the motor itself.

For a 6mm cutter: yes.

For a 20mm one: nope - the spindle will just stall.

A servo can create full torque at zero rpm - but the chinese spindle is an induction motor with very low torque at low rpm (at least with regular VFDs - but also vector control has its limits).

I'd also worry about the ATCs bearings - if they are designed for 4000rpm they may not survive 10000.

The Chinese spindle is only an option if your bearings survive it and you don't need low rpm anymore.

ChristianMy CAM Software and CNC Controller: www.estlcam.com

-

09-21-2014, 05:50 PM #15

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

I've checked electronics and all seems fine. I cannot find any manuals on how to get into the motor so cannot check encoder myself.

Well I do have three tapmatic tapping heads but the plan would be to sell them and use thread mills. So I wouldn't need low rpm but I would need power to use a 20mm cutter.

But its a 4hp motor so should have plenty of power to run big cutters

Funny you say that a few months ago I had to replace the spindle bears as they went. So if there high rpm is a problems I could just get new ones

This is why I'm keen to get a bit more info on Chinese spindle but struggling

-

09-22-2014, 05:03 PM #16

Registered

Registered

- Join Date

- Oct 2012

- Posts

- 33

Re: Chinese 2.2kw Spindle - wanting full spec

no more thoughts Christian Knüll??

Similar Threads

-

Hardinge "TALENT 8/52" Oi-TB Larhe - Wanting to move axes while stopping spindle

By Superman in forum FanucReplies: 6Last Post: 05-05-2023, 07:42 AM -

Mini Mill X2 Spindle Head + VFD + Chinese Spindle= custom!

By diyengineer in forum Uncategorised MetalWorking MachinesReplies: 9Last Post: 12-26-2016, 10:04 PM -

Wanting Mach3 to control spindle on/off

By MikeFelitti in forum Spindles / VFDReplies: 0Last Post: 04-23-2014, 08:03 PM -

3ne-300 GN6 spindle full RPM

By clintw in forum FanucReplies: 5Last Post: 02-11-2014, 09:01 AM -

Okuma LC40 not going full spindle speed

By SRT Mike in forum OkumaReplies: 12Last Post: 03-20-2008, 04:02 AM

Reply With Quote

Reply With Quote