Hello everyone. I'm Khoa from Vietnam. After being interested in CNC for a while and having build two CNC Cframes from weld steel and used cast iron parts. I'm having me time to build a small milling machine for miniature works.

The machine travel X,Y,Z is 6x12x10".

Here is its linear rails-THK SHS20:

and 2005 double nut screws:

BT30 used spindle have been taken out from a taping machine.

1.1KW Grundfus motor.

The couple:

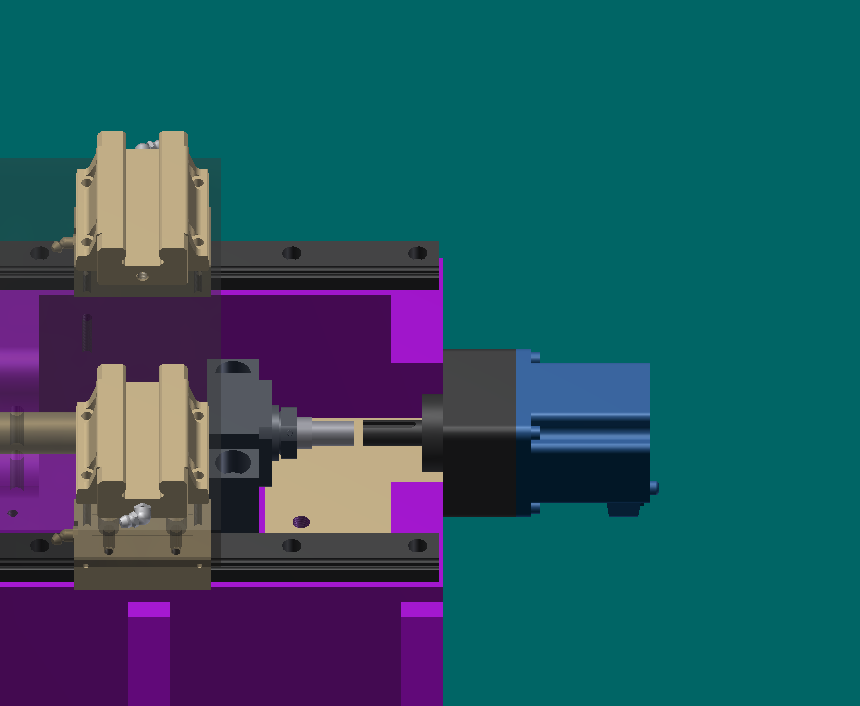

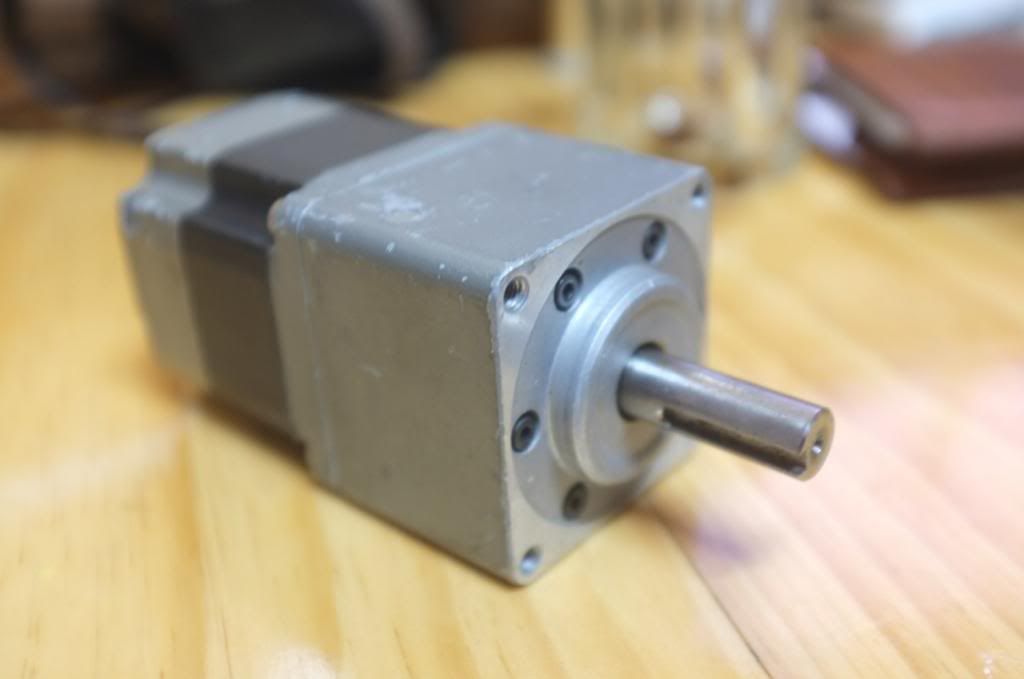

I will use ASM66AC-N5 and N10 for XYZ axis and ASM98AC-H100 for A axiss.

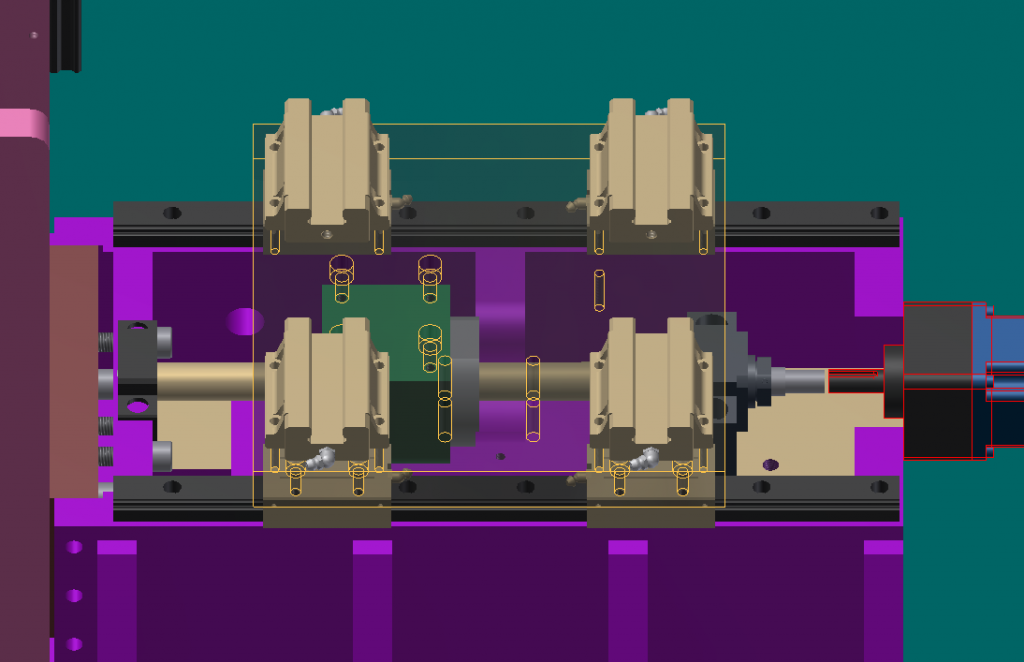

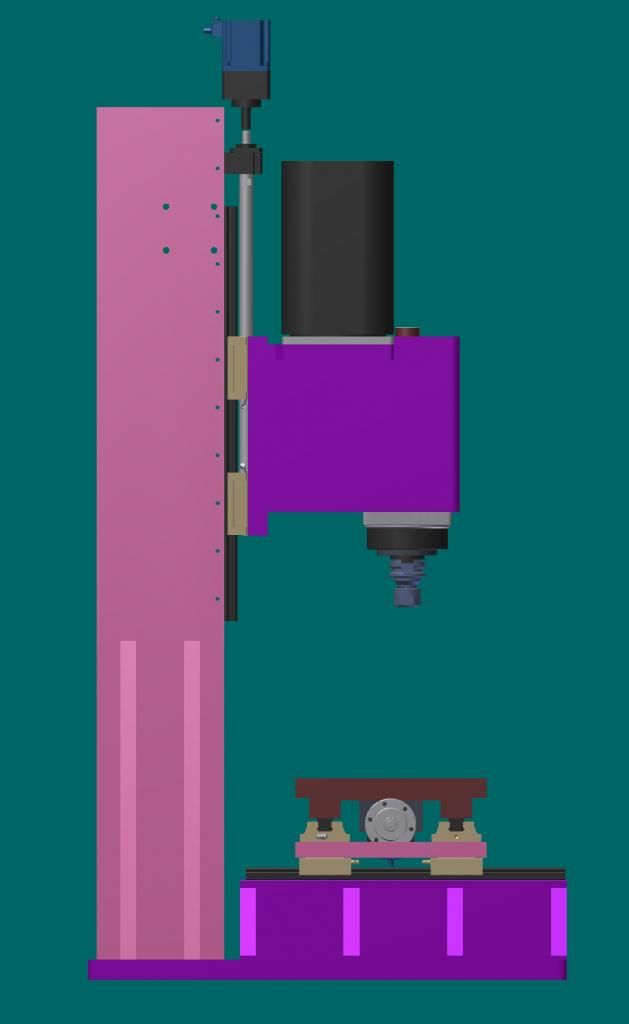

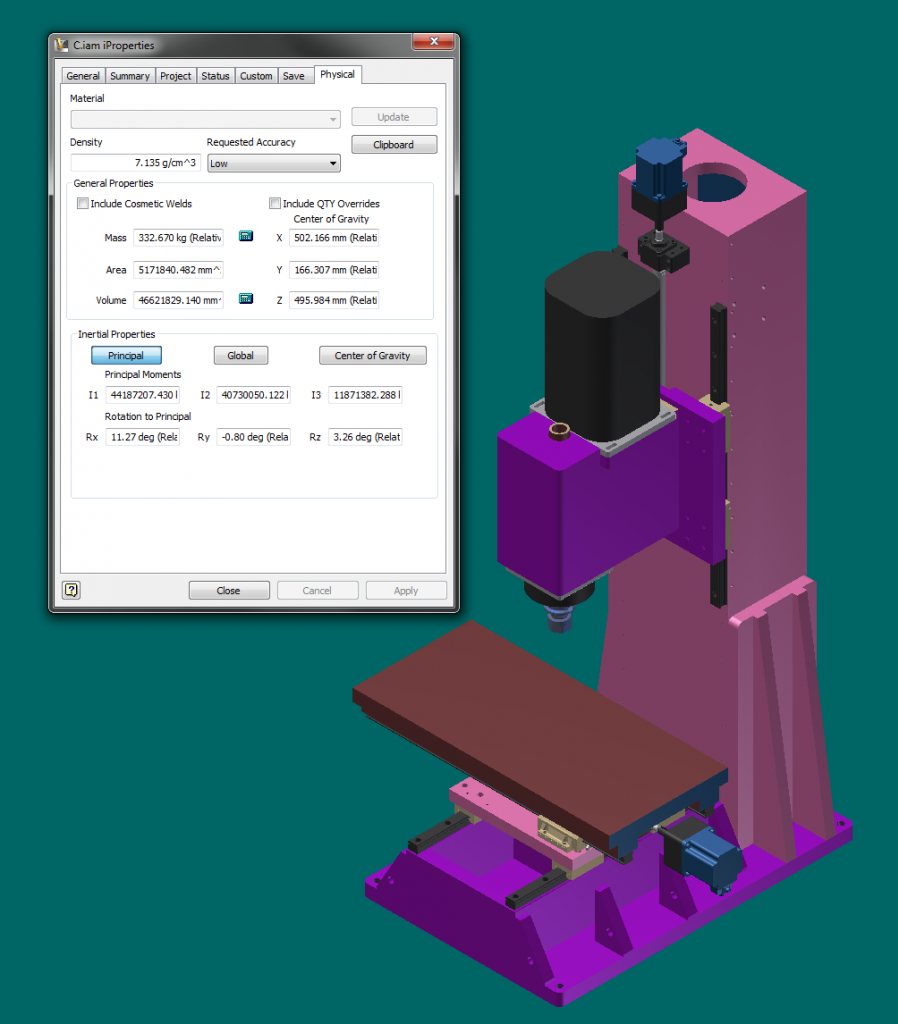

Here is the design:

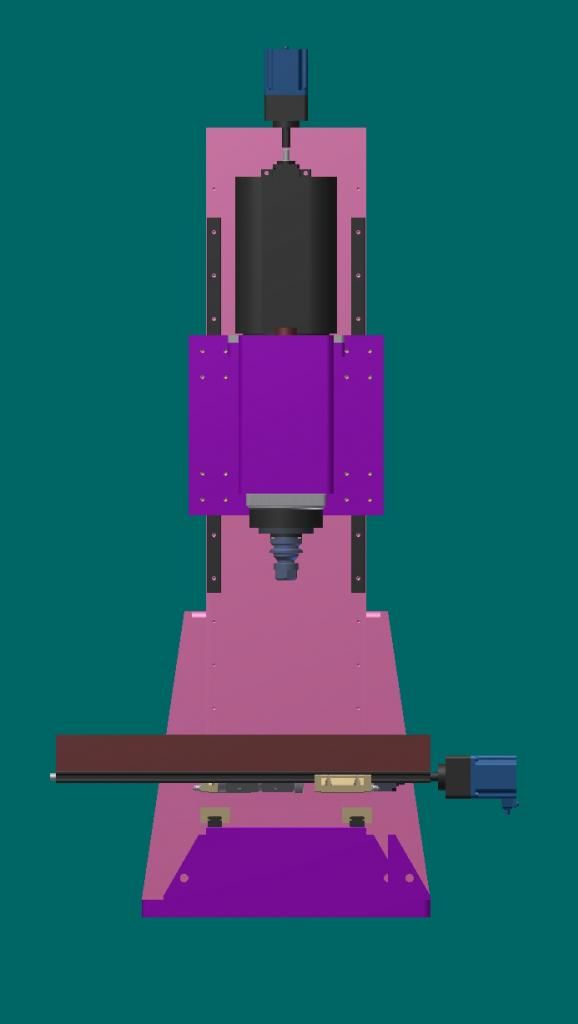

Side view:

Front view:

3/4 view:

The color of this machine will be pinky like a lovely Dinah.

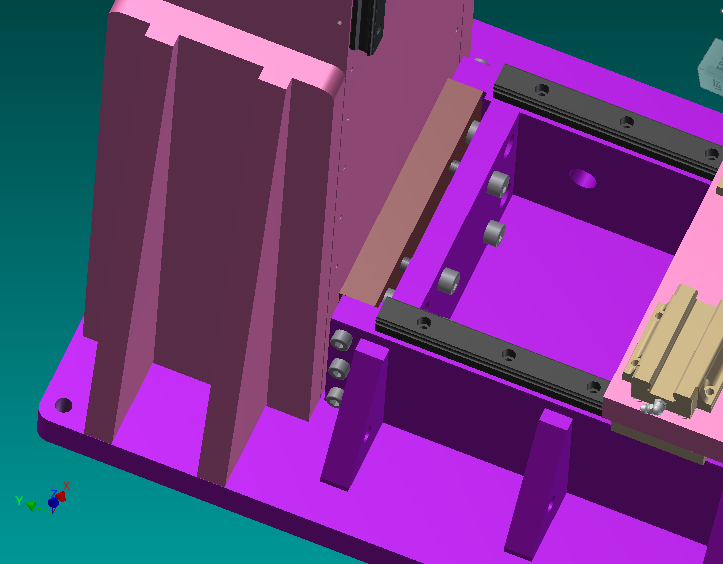

This structure is used for modifing the right angle between Z and XY axis.

After it's finished, all the empty parts will be filled by epoxy to make it more rigid. This machine weight is about 800 lbs.

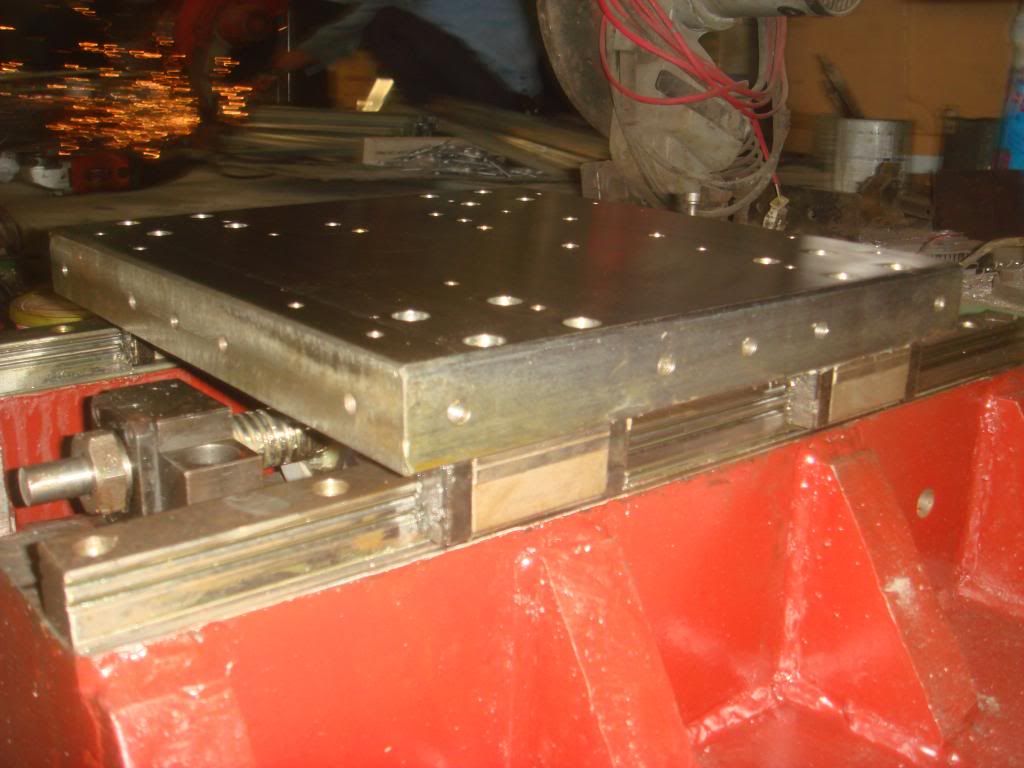

X, Y are made from 1" weld steel. Z is used iron casting bed.

Here is some pictures of the making process:

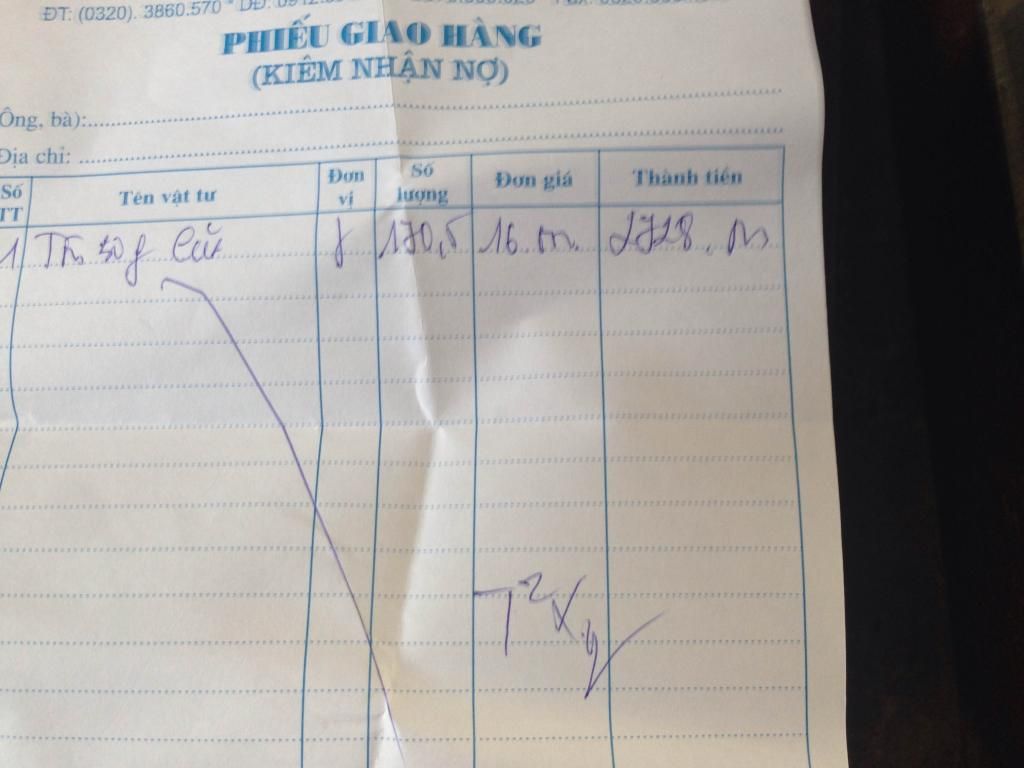

Here is steel for X table :

And the accident:

Thanks for reading. I will post more pictures about this build log while I make it.

Thread: 6x12 weld steel hobbies build.

Results 1 to 20 of 43

-

06-20-2014, 01:36 PM #1

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

6x12 weld steel hobbies build.

-

06-23-2014, 03:21 AM #2

Community Moderator

Community Moderator

- Join Date

- Mar 2003

- Posts

- 6855

Re: 6x12 weld steel hobbies build.

Looks good.

-

06-23-2014, 06:18 AM #3

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Thank you for your help Mr Paul. I appreciate it.

Here is my works for the past two days I couldn't update.

Welding at ~100 F is a challenge.

I've tried to put it in a milling machine. After 2 hours of refine, It's ready to go.

I've made some revisions on the design to make it fit with what I get in hand.

[imghttp://i158.photobucket.com/albums/t91/cuckilaoca_photo/PhotoShare564900PM.png[/img]

-

06-24-2014, 03:16 PM #4

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Here is some pictures for a day.

20mm diameter ball screw looks quite small for the Y axis.

It's a beauty arm for Z axis, isn't?

-

06-26-2014, 12:23 AM #5

Junior Member

Junior Member

- Join Date

- Jan 2011

- Posts

- 38

Re: 6x12 weld steel hobbies build.

Shouldn't you stress relieve that before final machining? Its far cheaper to do that then trying to fix warping later.

Also it feels like the part of the bed directly under the column is a little weak and might flex a bit during operation

-

06-26-2014, 07:24 AM #6

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

How many days it's needed for stress relieve? I welded and let it alone for 3 days before milling. I'm afraid of warping so I've not ground it.

Here is what it looks like underneath the Y bed :

And there are two square angle parts (don't know what it's called) on both side of the Z column. It's welded to the Y bed and connected with the Z column by screws.

and the assembly:

This machine is made mainly for machining brass.

-

06-26-2014, 09:03 AM #7

Junior Member

Junior Member

- Join Date

- Jan 2011

- Posts

- 38

Re: 6x12 weld steel hobbies build.

I was thinking more of a furnace at 1100 degrees for 3 to 4 hours based on the size of your part. Here in the US something like that would cost around $80~100 to stress relieve for 200lbs.

If there are no furnace you can get to, you can leave the whole thing outside for 3-4 month. Let the weather and rain do its work to surface rust it. hose it down with water occasionally and you should be able to reduce stress by up to 15%. This is based an on old navy welding book.

The third method is vibratory stress relieve, but its not something I am familiar with.

Anyway, if you are doing brass and have a tolerance of .005" then you might not need to stress relieve. Or the final method which works decently well for machine builders is to use fixtures or jigs to hold flat bars in alignment while injecting moglice/turcite/epoxy between it and the subframe.

here is an example, in the middle of the video, it shows you how to align the column and set it place. you can use similar practice to align the y axis

https://www.youtube.com/watch?v=URtU1XImjWE

-

06-28-2014, 04:15 PM #8

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Thank you for your help, Winterwatchers.

I've tried to look around to find a furnace service in my town but It seems like nobody cares about it here. I'm a bit worry about the 0.005" in tolerance. Actually the final accuracy in this machine I wanna reach is +-0.01mm. 4 months is too long to wait for. Can you give me some informations about vibratory stress relieve?

Khoa.

-

06-28-2014, 11:42 PM #9

Junior Member

Junior Member

- Join Date

- Jan 2011

- Posts

- 38

Re: 6x12 weld steel hobbies build.

0.01mm is really ambitious. In engineering field I find that .005"(0.12mm) is good enough for a lot of things and typically we compensate in our designs with that tolerance in mind. Anyway I can link you to the Wikipedia page that describes how it works. It's not something that is DIY friendly.

Vibratory stress relief - Wikipedia, the free encyclopedia

There is a method to stress relieve with a torch. basically you apply heat all over your weldment and slowly heat it up evenly. never leave the torch in one area for too long, keep moving it around. This is usually done on large building structures by very experienced welders and its a bit of a "dark art".

I suggest you use moglice/turcite method. You get a accurate flat granite surface plate, coat the area where you want to mount the THK rails with the resin. Either flip the welding upside down on top of the granite or put the flat granite against the top of the bed depending on which is convenient. Let it cure and then you will get a very accurate surface. Make sure you spray the granite beforehand with a releasing agent so the resin doesn't stick to it. Also machine little pockets on the bed to hold the moglice better.

this is a link to someone rebuilding their lathe using moglice.

Project: Reconditioning of my 250x550 Lathe (Very Picturheavy)

with this method, even if the bed warps over time you can just scrap the resin off and recoat again.

-

06-29-2014, 09:42 AM #10

Registered

Registered

- Join Date

- Aug 2004

- Posts

- 780

Re: 6x12 weld steel hobbies build.

This is an EXCELLENT, excellent build.

You wont have any trouble getting to 0.01 mm feature accuracy, imo, ime.

As far as overall accuracy, the screws are not that accurate over the total travel.

Mostly, this matters not at all, as in no-effect.

Where it may matter, you can

a. adjust programming to reflect that.

b. map or calibrate the screws

c. buy highly accurate screws later

1.

You accuracy is derived, gotten from, the linear guides themselves.

2.

The machine rigidity is gotten from the frame.

Your frame is the best I have seen anywhere, in the last 12 years.

3.

The motion-control rigidity and repeatability is gotten from the screw.

The thicker the screw, the better.

The 20 mm screw is adequate, because its short.

I scratch built a milling machine in steel, so these were my experiences.

You may or may not get warpage of the weldments.

I would think not, as your sections are very good, much better than I have seen anywhere.

Yet this depends on the welding stresses.

Stress relieving is simply heating the parts, and then cooling them slowly.

You can easily test, and directly feel, if there is any warpage, even later.

If you uncouple the leadscrew, you can easily move the carriages by hand, one finger is sufficient.

Example:

My milling machine table alone is 1600 mm wide, and 500 mm deep, and 60 mm thick (on ribs), in steel. (Its too thin, I know).

Its is about 200 kg in mass. With (one) vice, about 220 kg.

It is easily pushed by one finger. Takes about 5-7 kg force to start moving, and about 2 kg to keep moving.

Profiled linear guides, 20 mm on y.

As long as the movement is uniform, throughout the travel, it is not binding.

Any error over 0.01 mm is immediately apparent, as the linear guides get pretty stiff.

Its immediately obvious.

-

06-29-2014, 03:27 PM #11

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Thank you for your compliment. Here is my previous build.

[imghttp://i1298.photobucket.com/albums/ag59/sincerar/photo6_zpsd87f600f.jpg[/img]

-

06-30-2014, 05:31 PM #12

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

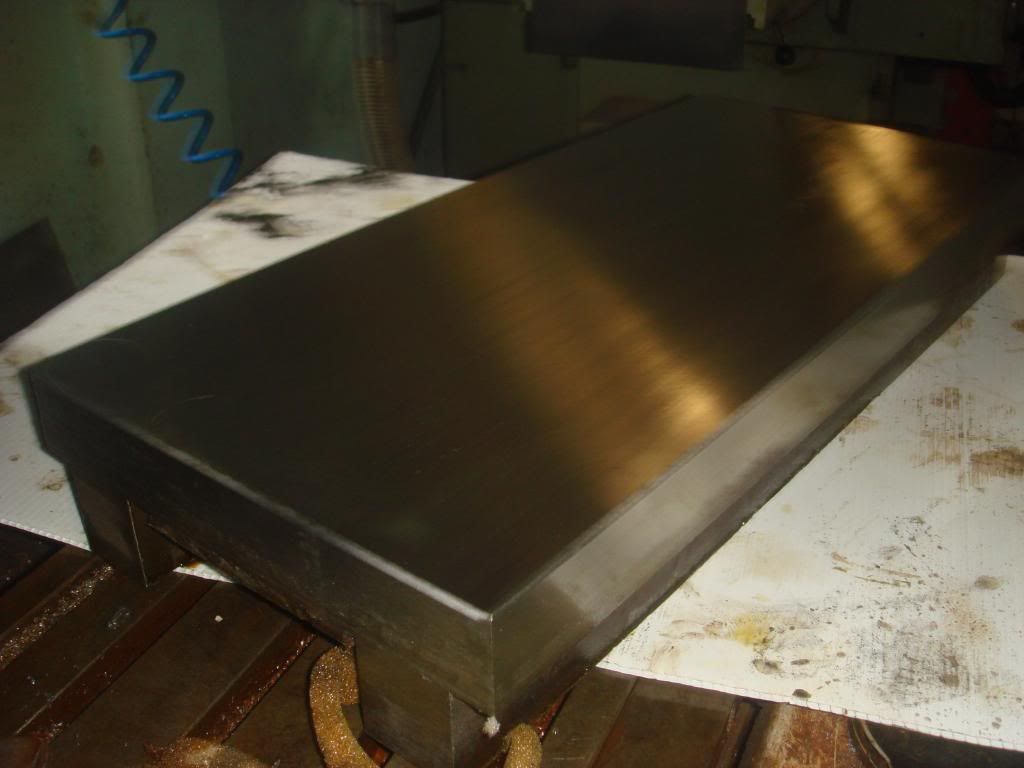

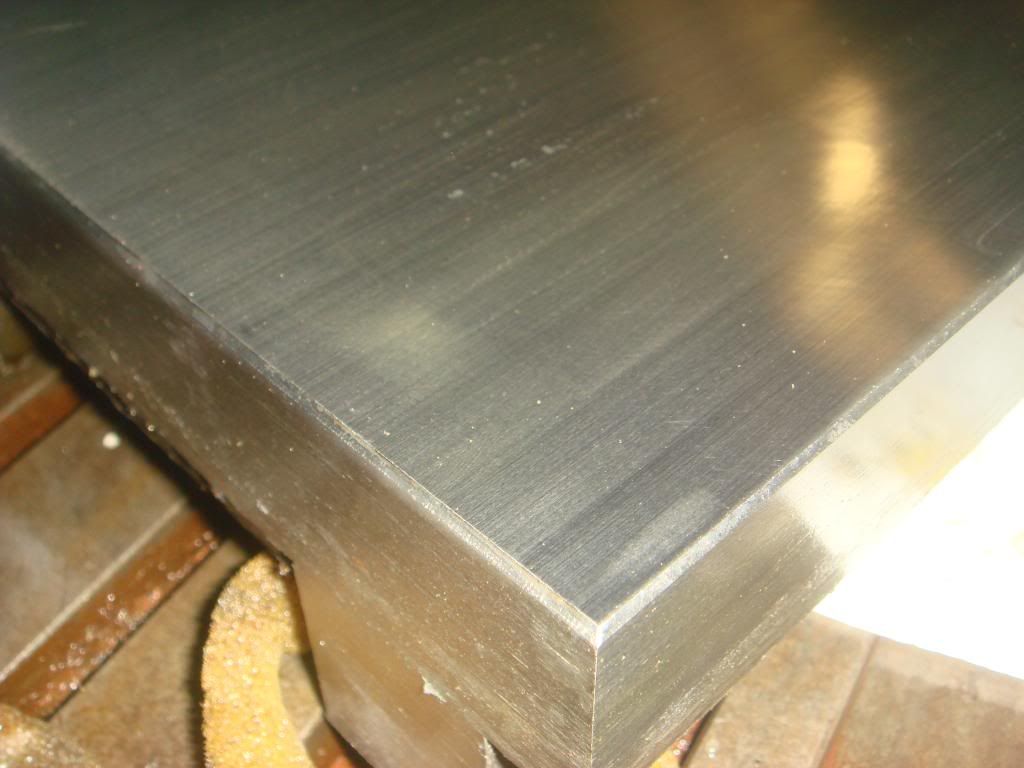

Here is my update on this machine. The XY flange, X axis table and some more works on Y axis.

X axis and the table:

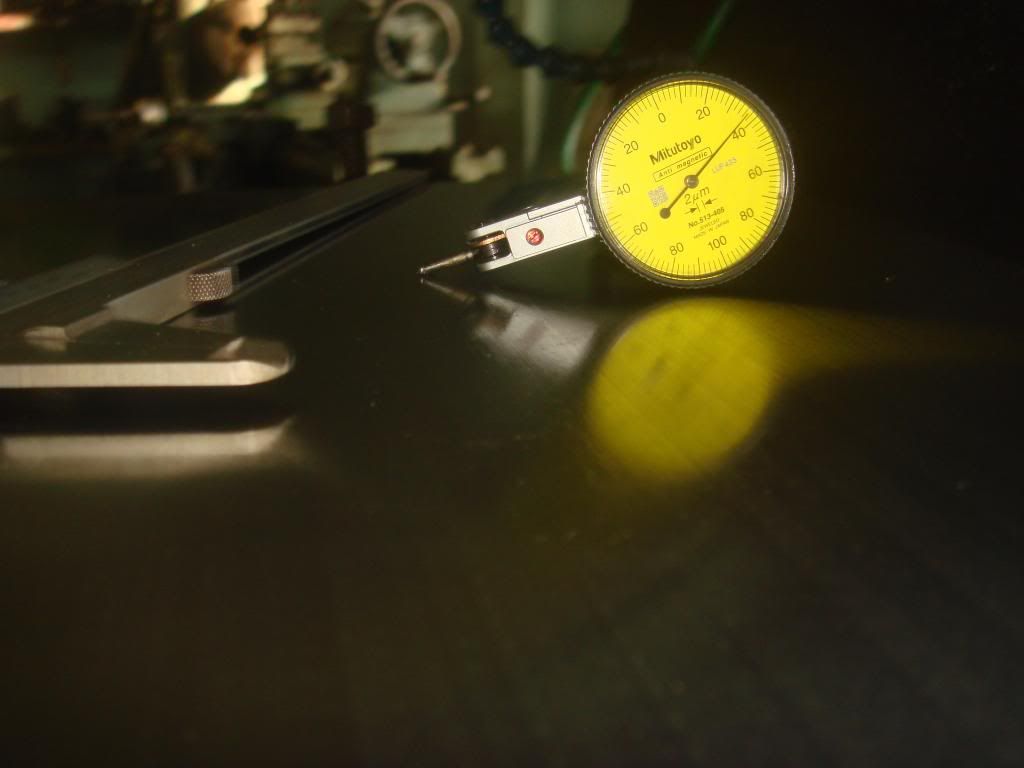

And Y axis grinding for poor man. I bought this machine for $700 for my DIY hobbies. The tolerance of final part is +-0.004mm:

It's enough for Monday. Thanks for reading.

-

07-03-2014, 01:20 AM #13

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Here are some more pics on the X axis that I'm milling:

-

07-03-2014, 12:31 PM #14

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Here are what I've waited for a long time. The X table is so stunning.

Grinding process:

Here is my perfect surface:

Thanks for reading.

Khoa

-

07-04-2014, 12:12 PM #15

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

I'm very exited to be a painter today. Here are my works:

Here is assembly parts. It fits perfect with my 3d model.

And the video:

I'm sorry for the background noise.

Thanks for watching!

Khoa

-

07-10-2014, 02:45 PM #16

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Come back to work after few days off. Here are my updates:

-

07-11-2014, 11:54 AM #17

Registered

Registered

- Join Date

- Jan 2010

- Posts

- 17

Re: 6x12 weld steel hobbies build.

Looks great and heavy!

Wil there be t-slots in your table? Or do you have other plans for it?

Keep posting pictures, I'm following your thread.

-

07-11-2014, 01:24 PM #18

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Thank you Assink for your compliment. I'm considering a GMT vise or a 20 cm 4-Jaw chuck. Most of my work pieces are not greater than 5".

Khoa

-

07-16-2014, 01:26 PM #19

Registered

Registered

- Join Date

- Apr 2012

- Posts

- 72

Re: 6x12 weld steel hobbies build.

Here is my update on this project:

It looks like a giraffe, doesn't it?

-

07-17-2014, 09:28 PM #20

Registered

Registered

- Join Date

- Mar 2013

- Posts

- 124

Re: 6x12 weld steel hobbies build.

How much do you think it weighs at this point?

Similar Threads

-

14x14 Linear Rail Industrial Hobbies Build (Charter Oak Automation)

By nateman_doo in forum Vertical Mill, Lathe Project LogReplies: 146Last Post: 03-06-2023, 08:14 PM -

My first cnc plasma table build 6x12

By jfoster in forum Plasma, EDM / Other similar machine Project LogReplies: 8Last Post: 01-28-2018, 08:16 AM -

No-Weld Steel 1 x 0.5 x 0.2m

By Benonymous in forum DIY CNC Router Table MachinesReplies: 49Last Post: 05-16-2012, 08:44 AM -

Weld Steel Green Machine

By R L Harris in forum CNC Wood Router Project LogReplies: 210Last Post: 10-10-2011, 09:22 PM -

Industrial Hobbies Build

By Mike Ray in forum Charter Oak Automation Support ForumReplies: 11Last Post: 01-16-2009, 03:24 PM

Reply With Quote

Reply With Quote