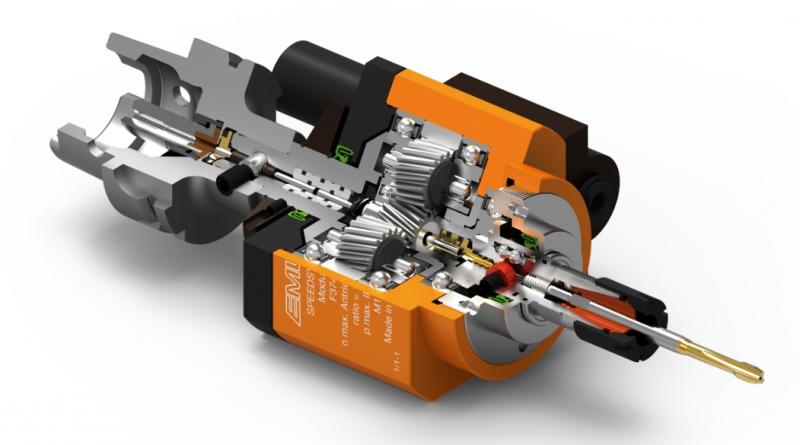

EMUGE, manufacturer of thread cutting and clamping tools in the EMUGE-FRANKEN company group, introduces a new modular version of the collet holder Speedsynchro

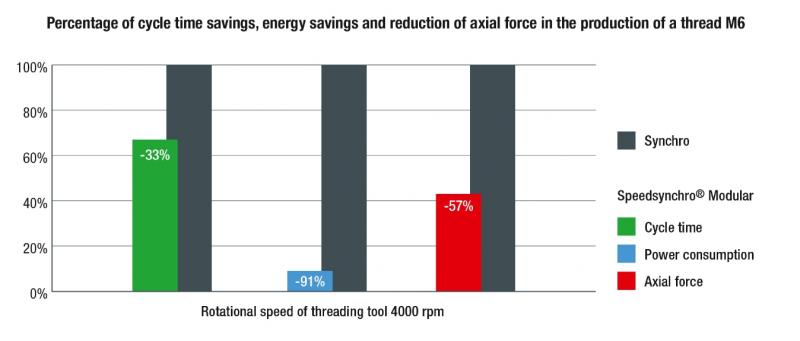

With smaller thread diameters in particular, CNC machine tools often do not realize the programmed rpm due to the limited synchronous control. Then thread cutting tools are not operated with the ideal cutting speed which may have a negative impact on the cycle time and tool life of the threading tool.

The collet holder Speedsynchro Modular is provided with an integrated transmission gearing which produces a 4.41 times increase of the RPM of the machine spindle at the tool. The consequently resulting higher cutting speeds reduce the cycle time by up to 50 %. At the same time the machine spindle can be operated in a lower speed range and so save up to 91 % energy.

In addition, the Speedsynchro Modular is equipped with the EMUGE minimum length compensation Softsynchro reducing the axial forces onto the workpiece. This results in a higher tool life and an improved thread quality. The Speedsynchro Modular is available in two versions: for use with coolant lubricant or for use with minimum quantity lubrication (MQL). The quick adaptation of the tool shanks to male and/or female center or the change between 1- and 2-channel MQL-system is guaranteed by simple exchange of the transfer elements and length adjustment screws. For large series manufacturers the Speedsynchro Modular delivers a quick contribution to more efficiency. Depending on the application an amortization is possible from about 250.000 threads.

Germany

Germany