DMG MORI

Products

DMG MORI Global Marketing GmbH

Portal milling machines

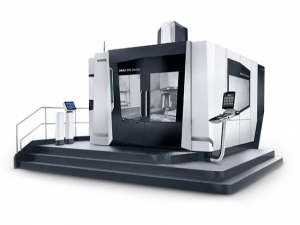

DMC 340 U

| Workspace |

|

| 3400 mm | |

| 1960 mm | |

| 10000 kg | |

| Travel |

|

| 3400 mm | |

| 3400 mm | |

| 2000 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 10,200 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- Pallet changer for main time parallel setup as standard

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

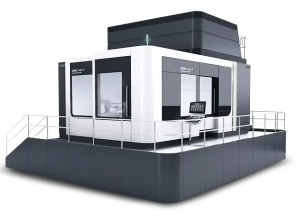

DMU 200 Gantry

|

Portal milling machine

DMG MORI

Portal milling machines

| Workspace |

|

| 4300 mm | |

| 2000 mm | |

| 1250 mm | |

| 20000 kg | |

| Travel |

|

| 4000 mm | |

| 2000 mm | |

| 1200 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

Dynamic Gantry design machine for the machining of large workpieces

Flexibility through spindle versions

Working area concept

Low Gantry Design

5-axes machining

Flexibility through spindle versions

- 45° head and 90° head for 5-axes machining up to 20,000 rpm

- Ready for new technologies like Ultrasonic, Laser or machining of carbon material

Working area concept

- Fixed table 2,250 x 2,000 mm with 10,000 kg loading capacity

- T-slots across the table for easy chip removal

- Chip conveyors on both sides of the table

Low Gantry Design

- 50 m/min rapid traverse

- Best visibility into the working area through missing side walls

- Maximum utilisation of the working area

- Modularly expandable in the X-axis up to 4,000 mm

- Machining of workpieces up to 20 t (with X-axis option 4,000 mm

5-axes machining

- 45° head with 90° swivel range and +/- 300° rotating range

- compactMASTER spindle with 20,000 rpm

- 90° head with +/- 120° swivel range and +/- 300° rotating range

- compactMASTER spindel with 20,000 rpm

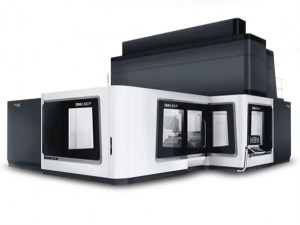

DMU 340 Gantry

|

Portal milling machine

DMG MORI

Portal milling machines

| Workspace |

|

| 7000 mm | |

| 3140 mm | |

| 1540 mm | |

| 30000 kg | |

| Travel |

|

| 6000 mm | |

| 2800 mm | |

| 1500 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

Dynamic machining of large workpieces

Precision

Performance

Efficiency

Highest rigidity and dynamics up to 5 m/s²

Precision

- Maximum accuracy through water-cooled feed drives

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 40,000 mm/min

- High feed power up to 50 kN

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Highest rigidity and dynamics up to 5 m/s²

- Thermosymetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 15 µm

- Position accuracy down to 12 µm with accuracy pack option

- Short and continuous throat depth of milling head (no ram design)

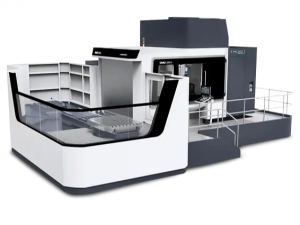

DMU 600 Gantry linear

|

Portal milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 18000 mm | |

| 2800 mm | |

| 2500 mm | |

| 150000 kg | |

| Travel |

|

| 18000 mm | |

| 4500 mm | |

| 2000 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The high-gantry machine in XXL size

Precision

Performance

Precision

- Direct Drive technology in all axes for superior surface quality and highest dynamic (linear drives: X, Y, Z axes; torque drives: A, C rotary axes)

- Large closed-loop control spectrum and free from gear meshing frequencies

- Fewer contouring errors compared to rack and pinion drive technology

Performance

- Ram in the Z axis with strokes up to 2,000 mm

- Y axis crossbeam with 3,500 mm and optional 4,500 mm traverse

- The X axis, 6,000 mm as standard, can be freely extended

Efficiency

Maximum rigidity

- Optimised Thermoshield technologies

- Long-term accuracy with the contact-free drive.

- 5-year warranty on linear motors

Maximum rigidity

- Unique precision with linear motors.

- For static and dynamic stiffness optimised machine structure.

- Geometric stability with structural cooling.

- Maximum stiffnes with FEM-optimised machine structure

- Crossbeam, X axis beds, Ram, Y / Z slidefrom EN-GJS-600-3 (GGG60)

DMU 210 P

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 2500 mm | |

| 1460 mm | |

| 8000 kg | |

| Travel |

|

| 2100 mm | |

| 2100 mm | |

| 1250 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Highest rigidity and dynamics up to 6 m/s²

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 6,800 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 980 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- High feed power up to 40 kN

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 303 tools with minimized footprint.

Highest rigidity and dynamics up to 6 m/s²

- Thermosymetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 10 µm

- Position accuracy down to 8 µm with accuracy pack option

- Worldwide unique high precision varinat µPrecision with Position accuracy down to 4 µm

DMU 270 P

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 3400 mm | |

| 1960 mm | |

| 12000 kg | |

| Travel |

|

| 2700 mm | |

| 2700 mm | |

| 1600 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Highest rigidity and dynamics up to 5 m/s²

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 11,000 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- High feed power up to 45 kN

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Highest rigidity and dynamics up to 5 m/s²

- Thermosymetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 12 µm

- Position accuracy down to 9 µm with accuracy pack option

- Worldwide unique high precision varinat µPrecision with Position accuracy down to 6 µm

DMU 340 P

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 3900 mm | |

| 1960 mm | |

| 20000 kg | |

| Travel |

|

| 3400 mm | |

| 3400 mm | |

| 2000 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Highest rigidity and dynamics up to 5 m/s²

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 10,200 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 40,000 mm/min

- Also available in mill- /turn - version

- High feed power up to 50 kN

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Highest rigidity and dynamics up to 5 m/s²

- Thermosymetrical construction

- 3-point support with an inherently stiff machine bed, no foundation required

- High temperature stability standard with positioning accuracy down to 15 µm

- Position accuracy down to 12 µm with accuracy pack option

- Short and continuous throat depth of milling head (no ram design)

DMU 600 P

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 3200 mm | |

| 18750 mm | |

| 3000 mm | |

| 2500 mm | |

| 80000 kg | |

| Travel |

|

| 18750 mm | |

| 4800 mm | |

| 3500 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

Universal machine in XXL size for 5-side / 5-axis machining of large workpieces

Precision

Performance

Efficiency

Maximum rigidity

Precision

- Maximum stiffness and high temperature stability

- All relevant heat sources are liquid-cooled

- Optimised machine concept based on FEM and modal analysis in portal design

Performance

- Also available in mill- /turn - version

- Large working area for work pieces up to 6,000 mm x 3,000 mm and 25,000 (40,000) kg

- Main drive with 53 kW and 1,445 Nm torque, optional 60 kW and 2,500 Nm torque

- Changeable heads with B-axis kinematics for gear spindle and C-/A- and C-/B-axis kinematics for motor spindle

Efficiency

- Energy-efficient coolant units

- Optional conncection to on-site / customer-site cooling circuit

- Version with double table and multi table available.

Maximum rigidity

- Shortest installation times through modular design of individual assembly groups

- Gear rod drive in the X-/Y-axis

- Ball screw drive in Z-/ W-axis for highest dynamics

- Machine bed, column and crossbeam from EN-GJS-600-3 with excellent damping characteristics

- Large dimensions with high temperature stability

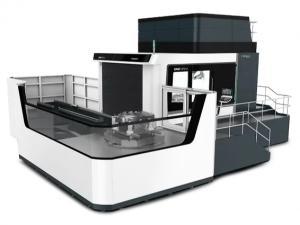

DMC 210 U

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 2500 mm | |

| 1460 mm | |

| 6000 kg | |

| Travel |

|

| 2100 mm | |

| 2100 mm | |

| 1250 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 6,800 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 980 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- Pallet changer for main time parallel setup as standard

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 303 tools with minimized footprint.

DMC 270 U

|

Portal and Gantry type milling machine

DMG MORI Global Marketing GmbH

Portal milling machines

| Workspace |

|

| 3400 mm | |

| 1620 mm | |

| 9000 kg | |

| Travel |

|

| 2700 mm | |

| 2700 mm | |

| 1600 mm | |

| Machine control |

|

| Heidenhain, Siemens | |

The portal series from DECKEL MAHO – more than 1,000 machines installed.

Complete machining

Precision

Performance

Efficiency

Complete machining

- Milling and turning in one setup with the DirectDrive table with a torque up to 11,000 Nm

- Best surface quality with technology integration grinding

Precision

- Maximum accuracy through water-cooled feed drive

- Band filter unit with 2,500 l as standard

- Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

- High dynamics with feed speed up to 60,000 mm/min

- Also available in mill- /turn - version

- Pallet changer for main time parallel setup as standard

- Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

- Lower energy consumption through intelligent needs-based power units.

- Gantry design with vertically moving cross beam with hydraulic weight compensation.

- Fast innovative wheel type magazine with up to 243 tools with minimized footprint.